Introduction

Since starting out in 2006, Cross See Development Co., Ltd. has established itself as a reliable manufacturer and distributor of steel fences, including our popular steel grating fences, which have become a favorite among Thai real estate developers.

We take part in a wide array of property projects, from homes to commercial spaces, where our focus is on delivering fences that offer both style and security. Our products are tailored to meet diverse needs and are built to last against any weather, enhancing both the security and aesthetics of any area. We’re committed to adding value and improving the look and safety of our clients’ properties for years to come.

quality

safety

innovation

Cross see

straight

Cross See Development Co., Ltd. operates with a focus on the value and cost-effectiveness of our products. Our goal is for every piece we create to showcase our company’s potential and our commitment to detail and quality. We’re dedicated to designing products that are not only safe and durable but also aesthetically pleasing, all within an affordable price.

MESH FENCE PANEL

- COLD-DRAWN STEEL WIRE FOR CONCRETE REINFORCEMENT : TIS 747-2564 Welded into sturdy steel mesh, WELDED FABRIC STEEL FOR THE REINFORCEMENT OF CONCRETE : TIS 737-2549 Precision cutting and shaping are achieved through advanced automated machinery, all overseen by our ISO 9001:2015 certified quality management system.

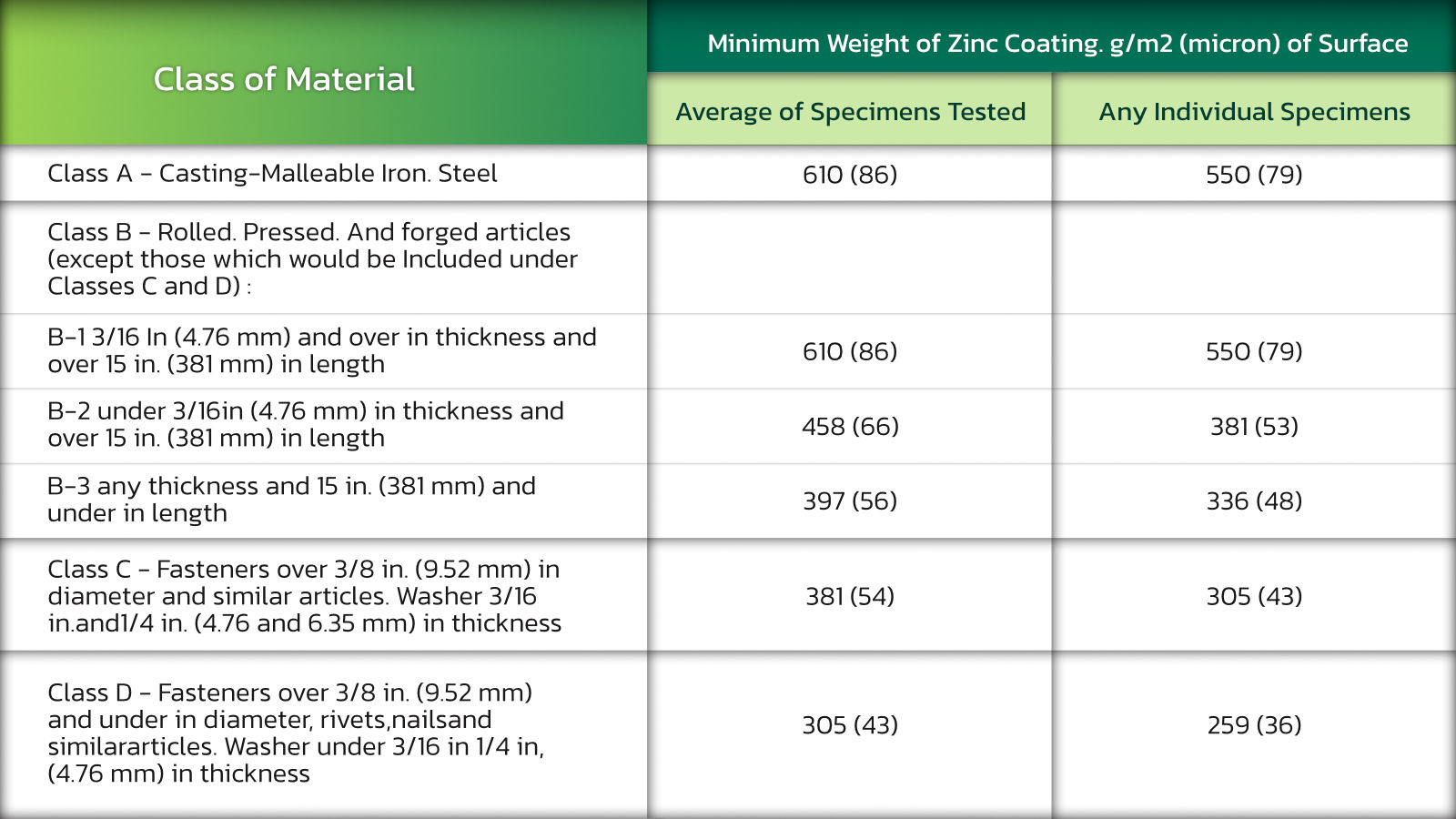

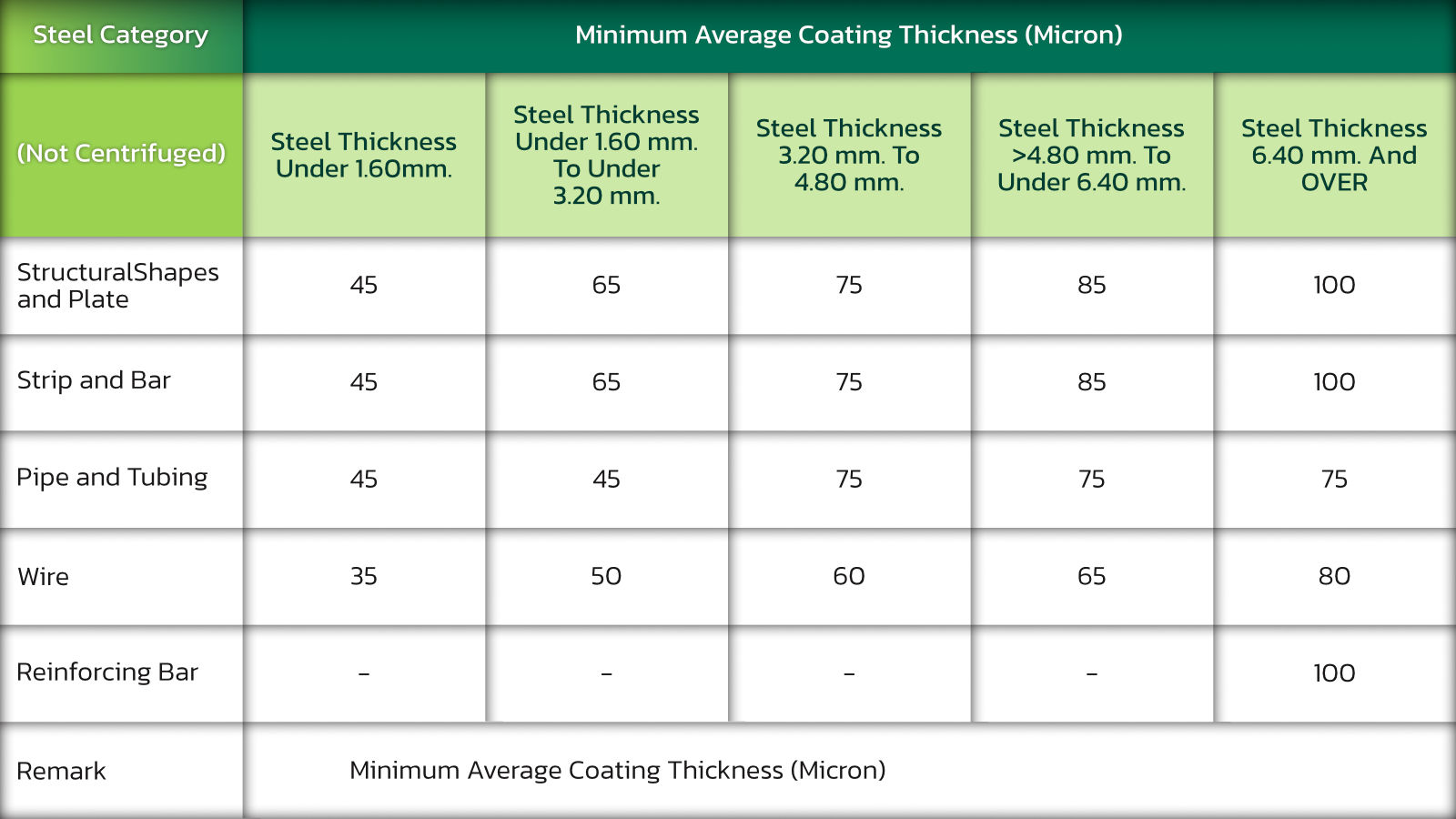

- Each panel is treated with a hot-dip galvanization process according to ASTM A123 Table 2 standards, ensuring optimal coating thickness as specified by ASTM A123 / A123M.

FENCE POST

- CARBON STEEL TUBES FOR GENERAL STRUCTURE : TIS 107-2561 Production involves advanced, automated machinery, ensuring high precision and meticulous detail.

- Each post receives a hot-dip galvanization treatment that meets the strict ASTM A123 Table 2 requirements, assuring that the coating thickness complies with ASTM A123 / A123M standards.

FIXINGS

- Installation Hardware: U-Clip, Bolt & Nut M8x1.25x90, and Stud Bolt ST1/2, our installation hardware undergoes a hot-dip galvanization process to meet ASTM A153 Table 1 standards, ensuring optimal coating thickness as specified by ASTM A153 / A153M.

Technologies

COATING TECHNIQUE AND COLORS

1. Hot Dip Galvanized after manufacture

We use hot-dip galvanizing technology to ensure that molten zinc thoroughly coats both the exterior and interior surfaces of our steel. This enhances the steel’s resistance to corrosion and effectively prevents rust. Additionally, our process is certified according to ASTM A123/A123M and ASTM A153/A153M standards

Standard and Specification of Galvanized Coatings

American Standards : ASTM A123 / A123M, A153 / A153M

British Standards : BS729

International Standards : BS EN ISO 1461

Australian Standards : AS1214, AS / NZS 4680

Japanese Standards : JIS H8641

Germany Standards : DIN 50976

2. Hot Dip Galvanized after manufacture and polyester powder-coated to match fencing

To achieve a polished and lasting finish, Cross See opts for a polyester powder coating process on our products after they undergo hot-dip galvanization. The coating has a thickness of 60-80 microns, complying with ISO 2360 standards, which offers excellent resistance to UV and weather changes. The colors are vibrant and durable, available in a selection of nine options including galvanized, green, black, brown, white, blue, yellow, red, and grey.”